LQ

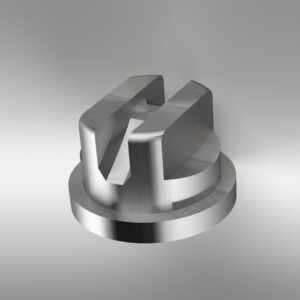

Spray Characterisitcs

- Produces a uniform flat fan shaped pattern.

- Requires minimal overlapping to produce an even distribution when used in multiple nozzle system.

- High pressure body design with replaceable insert.

- A wide range of flow rates and spray angles.

- 0° nozzle sizes available on request.

- Orifice offset -5° to axis of dovetail.

Construction and Materials

- Dovetail connection Nozzle/body for positive alignment.

- 3 piece construction. Body, tip and cap.

- The tip is dovetailed for self alignment.

- The orifice insert is manufactured in Tungsten Carbide for maximum wear resistance at higher pressures.

- The high pressure body, cap and orifice housing are manufactured in Stainless Steel as standard.

- Standard Male and Female thread bodies are available and also an optional welding body.

Order Example

- LQ 4 - 65° = Tip Only.

- 1/4" LQM (Male) 8 - 40° = Complete Assembly.

- LQW 2 - 65° = Welding Assembly.

Maximum Recommended Pressure: 350 Bar.G.}

Construction and Materials

- Dovetail connection Nozzle/body for positive alignment.

- 3 piece construction. Body, tip and cap.

- The tip is dovetailed for self alignment.

- The orifice insert is manufactured in Tungsten Carbide for maximum wear resistance at higher pressures.

- The high pressure body, cap and orifice housing are manufactured in Stainless Steel as standard.

- Standard Male and Female thread bodies are available and also an optional welding body.

Order Example

- LQ 4 - 65° = Tip Only.

- 1/4" LQM (Male) 8 - 40° = Complete Assembly.

- LQW 2 - 65° = Welding Assembly.

Maximum Recommended Pressure: 350 Bar.G.}

Construction and Materials

- Dovetail connection Nozzle/body for positive alignment.

- 3 piece construction. Body, tip and cap.

- The tip is dovetailed for self alignment.

- The orifice insert is manufactured in Tungsten Carbide for maximum wear resistance at higher pressures.

- The high pressure body, cap and orifice housing are manufactured in Stainless Steel as standard.

- Standard Male and Female thread bodies are available and also an optional welding body.

Order Example

- LQ 4 - 65° = Tip Only.

- 1/4" LQM (Male) 8 - 40° = Complete Assembly.

- LQW 2 - 65° = Welding Assembly.

Maximum Recommended Pressure: 350 Bar.G.}

Latest News

Keep up to date with the latest news from partners, events, our company and the wider industry.

Request a Consultation

Have questions about our spray-nozzles or fluid handling systems? Looking for help on a unique application? Need help with a budget estimate to determine overall equipment costs? Please don’t hesitate to reach out — we’d love to help.