Bypass™

Spray Characteristics

- Hollow cone spray pattern.

- “Turndown” refers to the ratio of the maximum discharge (bypass valve closed) to the minimum flow (bypass valve open) while maintaining satisfactory quality. Between these flow limits, there are no large fluctuations in spray angle or droplet size.

- The quality of atomization depends on nozzle capacity, turndown rating, and specific operating conditions. For example, a nozzle will produce finer droplets when the inlet pressure is higher than 42 Bar.G., and vice versa.

Delavan's Bypass™ nozzle has won an Honours Award in the Vaaler Awards competition held by Chemical Processing magazine. The product was judged as a major contribution toward more efficient and effective operation of plants in chemical processing industries.

APPLICATION

- Evaporative cooling, chemical processing.

Features

- Flow rate is changed by means of a bypass valve without varying the supply pressure of using atomizing air or gas. (See flow diagram).

- Reduces the number of nozzles needed when gas inlet temperatures vary.

- In a bypass system, a portion of the input liquid may be diverted through a return line by means of a bypass valve. As the valve is opened, the total input flow increases. Delavan's Bypass™ nozzle's patented design minimizes this flow growth to avoid excessive pumping requirements and hydraulic power consumption. The input flow increase (when bypass valve is opened) can be as low as 15%.

- Nozzle can be located in high temperature zone and connected by concentric piping to adaptor in cool area.

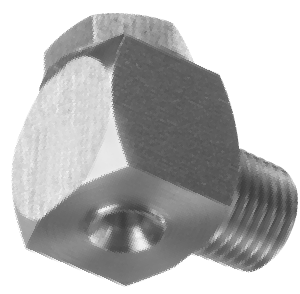

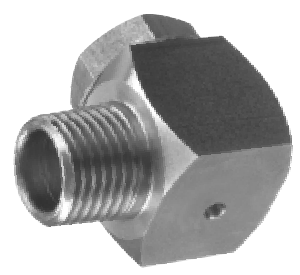

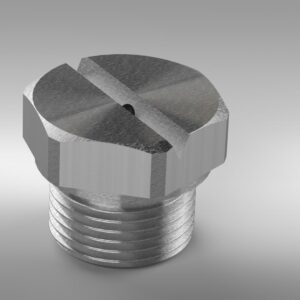

Construction and Materials

- Large passages, to minimize restriction and to avoid clogging.

- Nozzle cap and body easily removed from adaptor.

- Available in 316 L Stainless Steel only.

Order Example

- Refer to capacity chart for part numbers.

Maximum Design Pressure: 56 Bar.G.

Maximum Design Temperature: 540° (Bypass™ Nozzle), 150° (Adaptor).

Delavan's Bypass™ nozzle has won an Honours Award in the Vaaler Awards competition held by Chemical Processing magazine. The product was judged as a major contribution toward more efficient and effective operation of plants in chemical processing industries.

APPLICATION

- Evaporative cooling, chemical processing.

Features

- Flow rate is changed by means of a bypass valve without varying the supply pressure of using atomizing air or gas. (See flow diagram).

- Reduces the number of nozzles needed when gas inlet temperatures vary.

- In a bypass system, a portion of the input liquid may be diverted through a return line by means of a bypass valve. As the valve is opened, the total input flow increases. Delavan's Bypass™ nozzle's patented design minimizes this flow growth to avoid excessive pumping requirements and hydraulic power consumption. The input flow increase (when bypass valve is opened) can be as low as 15%.

- Nozzle can be located in high temperature zone and connected by concentric piping to adaptor in cool area.

Construction and Materials

- Large passages, to minimize restriction and to avoid clogging.

- Nozzle cap and body easily removed from adaptor.

- Available in 316 L Stainless Steel only.

Order Example

- Refer to capacity chart for part numbers.

Maximum Design Pressure: 56 Bar.G.

Maximum Design Temperature: 540° (Bypass™ Nozzle), 150° (Adaptor).

Delavan's Bypass™ nozzle has won an Honours Award in the Vaaler Awards competition held by Chemical Processing magazine. The product was judged as a major contribution toward more efficient and effective operation of plants in chemical processing industries.

APPLICATION

- Evaporative cooling, chemical processing.

Features

- Flow rate is changed by means of a bypass valve without varying the supply pressure of using atomizing air or gas. (See flow diagram).

- Reduces the number of nozzles needed when gas inlet temperatures vary.

- In a bypass system, a portion of the input liquid may be diverted through a return line by means of a bypass valve. As the valve is opened, the total input flow increases. Delavan's Bypass™ nozzle's patented design minimizes this flow growth to avoid excessive pumping requirements and hydraulic power consumption. The input flow increase (when bypass valve is opened) can be as low as 15%.

- Nozzle can be located in high temperature zone and connected by concentric piping to adaptor in cool area.

Construction and Materials

- Large passages, to minimize restriction and to avoid clogging.

- Nozzle cap and body easily removed from adaptor.

- Available in 316 L Stainless Steel only.

Order Example

- Refer to capacity chart for part numbers.

Maximum Design Pressure: 56 Bar.G.

Maximum Design Temperature: 540° (Bypass™ Nozzle), 150° (Adaptor).

Latest News

Keep up to date with the latest news from partners, events, our company and the wider industry.

Request a Consultation

Have questions about our spray-nozzles or fluid handling systems? Looking for help on a unique application? Need help with a budget estimate to determine overall equipment costs? Please don’t hesitate to reach out — we’d love to help.