PU

Spray Characteristics

- Produces a hollow cone spray patterns using an external pintle deflector.

- Relatively uniform distribution at low pressures.

- Produces coarser droplets than a normal hollow-cone spray.

- Standard spray angle is 164° but is available with other spray angles.

- The pintle deflector is spring loaded and will “pop-up” under pressure to produce the spray pattern. When the pressure reduces the pintle returns to its seat to prevent ingress from the external process.

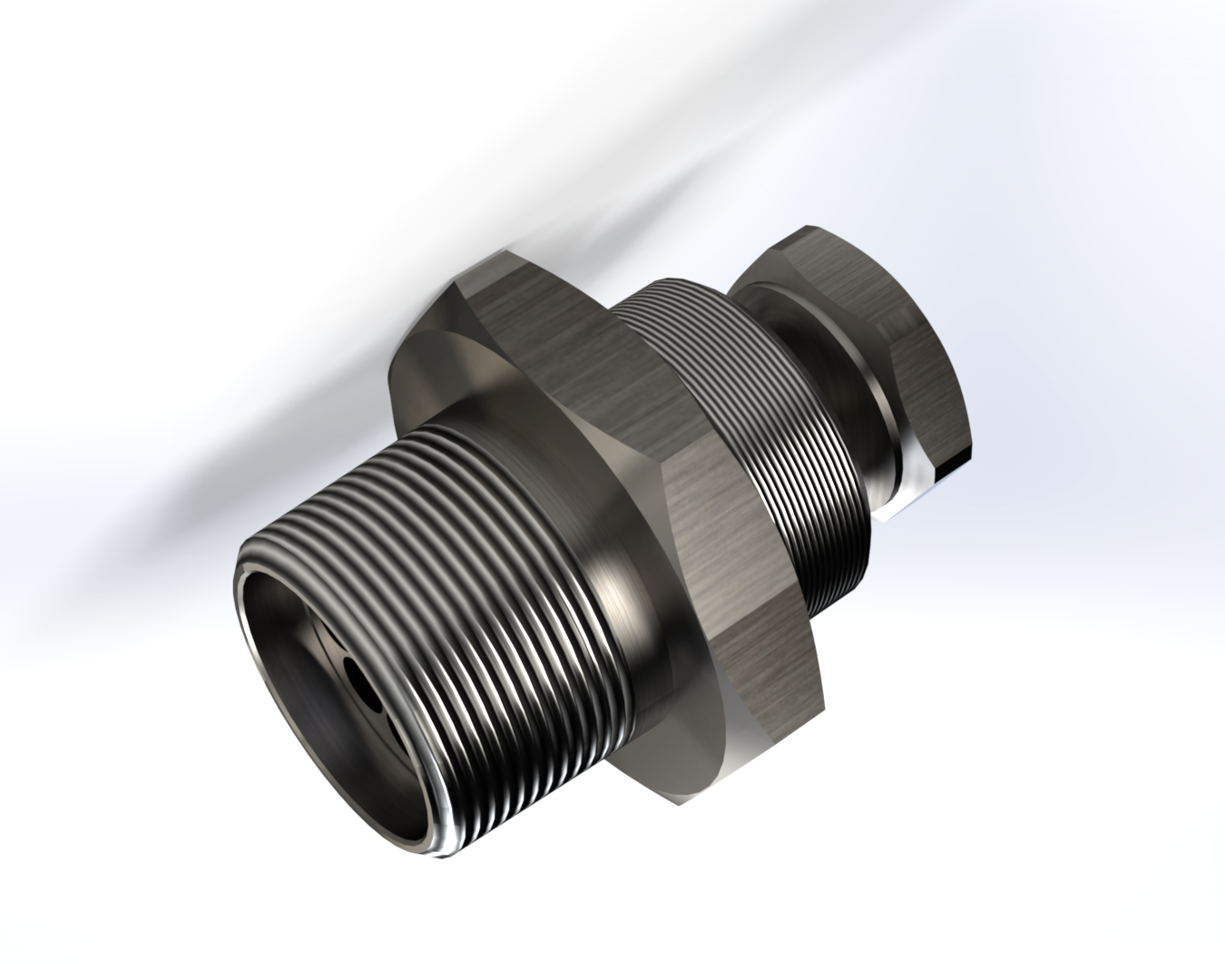

Construction and Materials

- In line design, manufactured in 3/4" BSPT Male Thread only.

- The front of the nozzle is threaded 3/4" BSPP for socket or plate mounting to allow Installation through the floor of a vessel.

- Pintle design can be varied to allow for different spray angles

- Manufactured in 316 Stainless Steel as standard with 302 Stainless Steel spring.

- Other materials to special order.

APPLICATION

- Cleaning the base of mash tuns the brewing industry. The PU Nozzle sits flush in the base of the mash tun and at the end of the brewing process the tanks are drained leaving the mash waste at the bottom. The spring loaded nozzles open under pressure, clean the surrounding area and retract at the end of the wash cycle eliminating the chance of blockages with in the nozzles

Order Example

- 3/4" PU 80 Stainless Steel.

Maximum Recommended Pressure: 14 Bar.G.

Construction and Materials

- In line design, manufactured in 3/4" BSPT Male Thread only.

- The front of the nozzle is threaded 3/4" BSPP for socket or plate mounting to allow Installation through the floor of a vessel.

- Pintle design can be varied to allow for different spray angles

- Manufactured in 316 Stainless Steel as standard with 302 Stainless Steel spring.

- Other materials to special order.

APPLICATION

- Cleaning the base of mash tuns the brewing industry. The PU Nozzle sits flush in the base of the mash tun and at the end of the brewing process the tanks are drained leaving the mash waste at the bottom. The spring loaded nozzles open under pressure, clean the surrounding area and retract at the end of the wash cycle eliminating the chance of blockages with in the nozzles

Order Example

- 3/4" PU 80 Stainless Steel.

Maximum Recommended Pressure: 14 Bar.G.

Construction and Materials

- In line design, manufactured in 3/4" BSPT Male Thread only.

- The front of the nozzle is threaded 3/4" BSPP for socket or plate mounting to allow Installation through the floor of a vessel.

- Pintle design can be varied to allow for different spray angles

- Manufactured in 316 Stainless Steel as standard with 302 Stainless Steel spring.

- Other materials to special order.

APPLICATION

- Cleaning the base of mash tuns the brewing industry. The PU Nozzle sits flush in the base of the mash tun and at the end of the brewing process the tanks are drained leaving the mash waste at the bottom. The spring loaded nozzles open under pressure, clean the surrounding area and retract at the end of the wash cycle eliminating the chance of blockages with in the nozzles

Order Example

- 3/4" PU 80 Stainless Steel.

Maximum Recommended Pressure: 14 Bar.G.

Latest News

Keep up to date with the latest news from partners, events, our company and the wider industry.

Request a Consultation

Have questions about our spray-nozzles or fluid handling systems? Looking for help on a unique application? Need help with a budget estimate to determine overall equipment costs? Please don’t hesitate to reach out — we’d love to help.