SDX® Spray

Drying Nozzles

Delavan Spray Drying Nozzles reflect years of dedication to quality, flexibility and reliability. Since 1935, the Delavan name has become synonymous with precision engineering, proven techniques and product satisfaction.

The Quality you’ve come to expect

Today Delavan continues to be a leader in the spray drying industry by staying on the forefront of research and development in new materials, delivery systems and designs to handle new challenges across a range of industries. In 1957, Roger W. Tate joined Delavan as the Director of Research, and within a few years the eccentric spiral swirl chamber nozzle was born.

SDX® Range

This tradition started with the original SDX® Nozzle and continues with the latest SDX® family of nozzles. This product line, specifically designed for the spray drying industry, includes five centrifugal pressure nozzles: the Mini SDX®, Compact SDX®, SDX®, SDX® III, and SDX® V.

Each of these five products is built on Delavan’s unique single inlet spiral swirl chamber design and highly polished orifice. The combination of the swirl chamber and orifice produces a limitless number of combinations, to supply virtually any flow-rate and spray angle. This means the nozzle can be ‘fine-tuned’ to almost any dryer or application.

High Performance, Rugged Durability

The Delavan SDX® range of spray drying nozzles set the standard by which other nozzles are judged. We were the first to hold a patent on the revolutionary swirl chamber design, with a single inlet, which minimises plugging and maximises particle uniformity. This design has improved dry product quality, as the spiral configuration conforms to the natural path of liquid as it progresses toward the orifice. Here at Delavan, when you talk we listen.

Delavan is continually evaluating the critical design features of the various models of nozzle that comprise the SDX® range. This engineering work, combined with feedback from thousands of users around the world, generates opportunities to improve the performance of the product as well as lowering the cost of ownership and simplifying maintenance. Significant recent enhancements to the SDX® range can be found within this updated product brochure.

An Investment in Quality and Performance

The substantial investment that Delavan has made in the last few years in state-of the- art machining centres has borne fruit in the improvements in quality and lead time reduction that have taken place since manufacturing was transferred to the centre of excellence for spray dry products at Widnes, in the UK. Combined with high technology laser marking and premium quality packaging this ensures that all genuine Delavan SDX® components reach customers in a timely fashion and in pristine condition.

Each of these five products is built on Delavan’s unique single inlet spiral swirl chamber design and highly polished orifice. The combination of the swirl chamber and orifice produces a limitless number of combinations, to supply virtually any flow-rate and spray angle. This means the nozzle can be ‘fine-tuned’ to almost any dryer or application.

Delavan offers:

- Durability and wear resistance

Our nozzles are available in materials that resist chemical attack such as plastics, ceramics, sintered carbides and various grades of stainless steel. - Customisation

To suit all your application needs, you can specify spray characteristics to meet your needs, including droplet size and particle size, spray angle, flow variation and properties of the liquid being sprayed. - Versatility

Delavan offers 3 swirl chamber configurations with orifice discs ranging in size from 0.4mm to 6.4mm. The large number of swirl chamber orifice combinations provide customers with more options when spray drying a variety of different products. Swirl chambers and orifices can be paired in a variety of combinations to produce the droplet size, flow rate, and spray angle and product quality needed to meet your exact product specifications. - Lifetime service and support. Once Delavan nozzles are installed in your dryer, the support never ends. You can contact Delavan at any time with changes, questions or issues.

- Computer Analysis – To suit all your application requirements, Delavan uses computer analysis programs to produce information such as droplet size, spray angle, flow rate – all this before installing any nozzles into the spray dryer, saving valuable time and money.

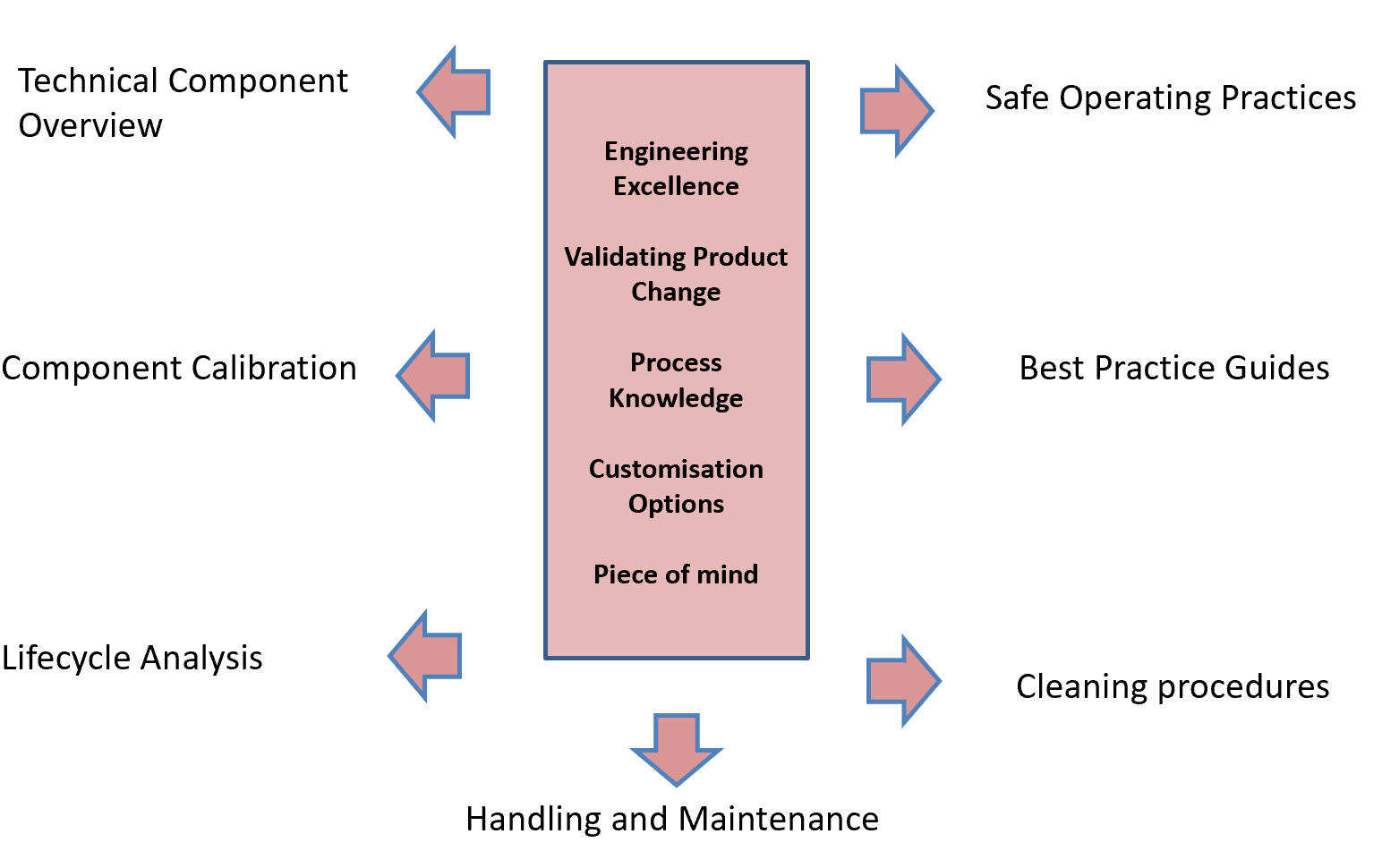

Our Technical support includes:

- Technical expertise and know how

Understanding the “custom” aspect of each application is of critical importance in spray drying. Almost every dryer presents a unique situation depending on feed material, capacity, and operating conditions. Delavan understands the conditions and problems inherent in spray drying and will recommend the right nozzle for the best performance. - Delavan’s application specialists are constantly working with end users and OEM’s globally to not only improve production processes and final powder quality, they are also working with operators to ensure alignment with our proven operating practices.

Critical CARE AND MAINTENANCE

The perception within the industry is that nozzle bodies and adaptors will last indefinitely, however this is far from the truth and just as much attention needs to be given to the Bodies and Adaptors as is applied to the Orifice Discs and Swirl Chambers. Where the Orifice Disc and Swirl Chamber condition has a direct relationship to spray quality the Nozzle Body and Adaptor condition has a direct relationship to smooth operation and nozzle safety.

The Delavan SDX® nozzle range has been specifically designed for high pressure applications with the SDX® III configuration being in service throughout the world for over 40 years. Each component throughout the SDX® range is precision machined to tested and proven dimensions with close tolerances to suit the exacting requirements demanded by the process.

In order to ensure that the nozzles continue to operate effectively it is vital that each component is handled carefully, ensuring that there is no damage to the components. This is particularly important with the sealing surface areas and the threads. Any slight damage to a sealing face or surface, or to a thread profile, can potentially cause an issue. If there is any doubt about the condition of a component then Delavan would suggest that the item is replaced.

The Delavan SDX® range of nozzles has been operating successfully and safely throughout the world for over 60 years. In developing the SDX® range independent high pressure cycling and proof pressure testing was commissioned in order to ensure that we can support the ever increasing demands of our customers, complying with ASME B31.3 standard.

Latest News

Keep up to date with the latest news from partners, events, our company and the wider industry.

Request a Consultation

Have questions about our spray-nozzles or fluid handling systems? Looking for help on a unique application? Need help with a budget estimate to determine overall equipment costs? Please don’t hesitate to reach out — we’d love to help.