General Troubleshooting Guide for Burner Nozzles

Like any intricate piece of equipment, certain conditions can affect an the performance of a burner nozzle. The troubleshooting guide below offers tips to address some of the most common causes for nozzle performance issues as well as some of the most Frequently Asked Questions by Heating Service Technicians.

Determining Burner Pattern

Following the appliance manufacturer’s specification, to establish the correct spray pattern, try a hollow cone nozzle with an 80° spray angle (a popular angle in the industry). If the pattern is not satisfactory, change to a solid cone nozzle. Reducing nozzle angle in 10 increments from 80° is a good way to find proper angle. (Mobile home units usually require 90° spray angles.)

Cold Fuel

Outside storage tanks can be a source of burner problems because liquid fuel becomes more viscous as the temperature drops. This, in turn, can result in slow ignition, collapsing sprays, and noisy fires. There have been some cases where the liquid fuel was so cold, it would not flow through the pipe.

Although some success with special nozzles has been reported, the surest cure for this problem is to increase the pump pressure following the specifications, as an example, to 120-145 psi, utilizing the chart. The extra energy from the pump will atomize the heavier fuel, resulting in better ignition and a more stable flame.

Delayed Ignition

Check the following items:

- Check for proper electrode setting.

- Check the insulators for cracks or for a conducting coat of soot or fuel. Cracks sometimes occur under the electrode bracket, causing a short circuit.

- Check to see that the combustion air

openings aren’t too wide open.

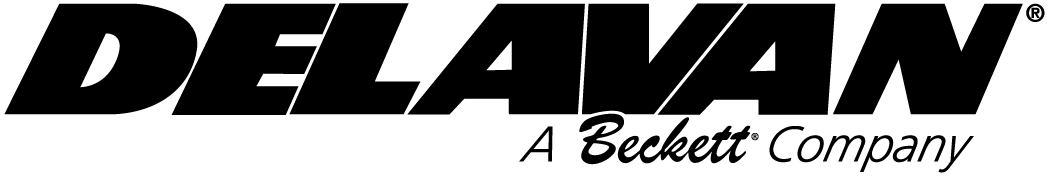

Figure 19 — follow manufacturer recommended Electrode Settings

Furnace Room Odors

In the case of furnace room odor, check these items:

- Check the draft over the fire and make sure it runs with positive pressure over the fire. If it’s lower than that, check for obstructions in the flues, or for poor chimney draft.

- Check to be sure that the unit is not being over fired.

- Check to see that there is not too much air through the burner.

- Delayed ignition also can be a cause of odors.

Want to Optimize Your Annual Appliance Tune-Up Service?

Talk to  !

!

Have questions about our Care & Service Tips for Burner Nozzles guide? Have a particular issue with a nozzle that you just can’t seem to troubleshoot? Have general questions about how to optimize your annual appliance tune-up service to maximize your profitability? We’d love to help! Click the button below to schedule a 1-on-1 consultation with a Delavan Technical Advisor.

Smoky Flames

Since there are a number of possible causes, there are several things to check:

- Check the air handling parts of the burner. Make sure the fan blades, air intake and air vanes in the combustion head are clean. If dogs or cats are kept in or near the furnace room, it’s not uncommon to find hair in the fuel burner fan.

- Check the combustion chamber or the burner tube for damage. In the case of a stainless steel chamber, it might be burned through in one or more places. In the case of a brick chamber, some of the bricks might have become dislodged, leaving openings. Sometimes a burner retention head will be burned off or warped.

- Check the nozzle for contamination. If clogged, it could produce an off-center flame, resulting in smoke.

- Going to a size smaller nozzle might eliminate smoke.

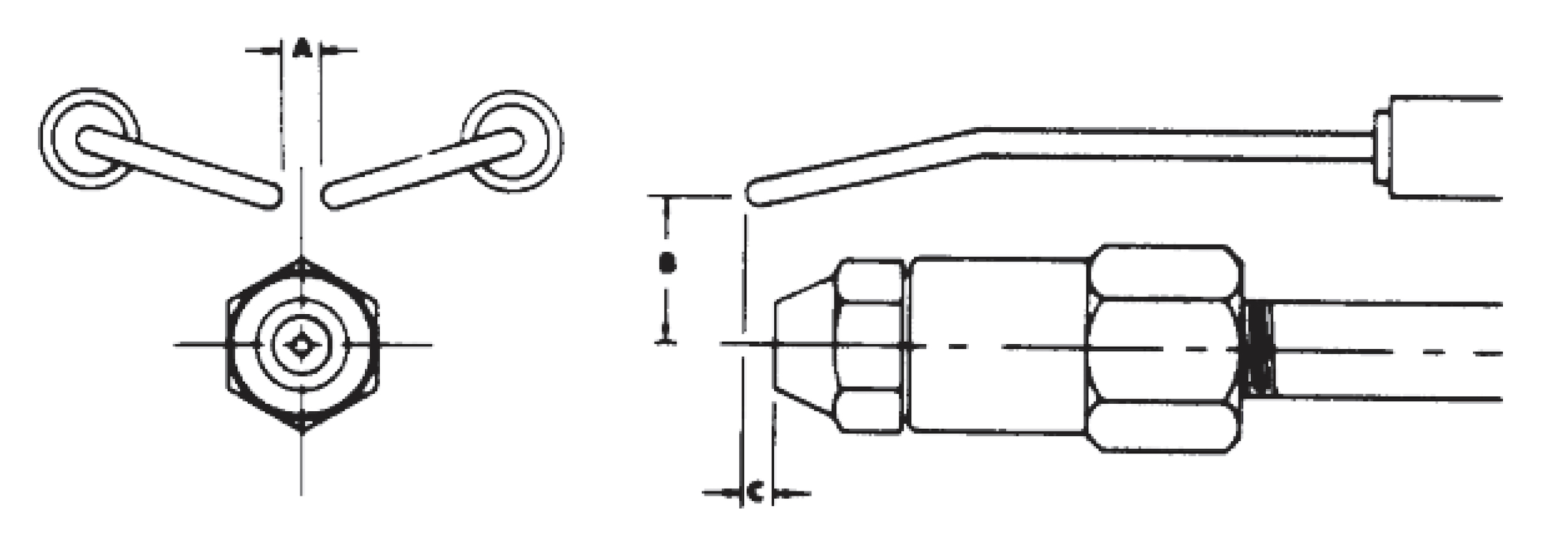

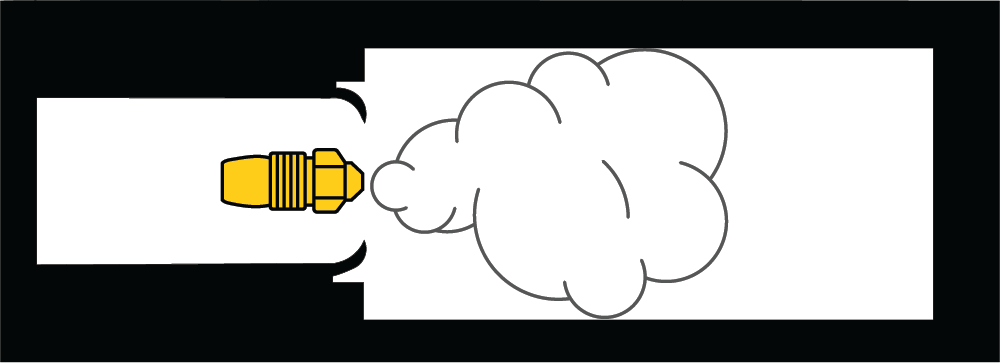

Figure 20

Spray impingement

Spray impingement corrected by using a narrower spray angle

- Check to see if nozzle spray angle is too wide for the burner air pattern. In this case, smoke may form at the side of the flame. The solution is to select the next narrower spray angle.

- A solid cone spray pattern in a burner with a hollow air pattern will produce a smoky center in the flame. This can be corrected by changing to a hollow cone nozzle of the proper spray angle.

- Check for spray impingement on the walls or floor of the combustion chamber, or at the end of the burner tube. This is a cause of carbon build-up and smoky flames. It’s usually corrected by the proper choice of spray angle or by going to a solid cone spray pattern. If it’s at the end of the burner tube, you may have to relocate the nozzle.

Noisy Flames

Pulsation and thumping or rumbling can be objectionable to a homeowner. It’s possible in some cases to correct the situation by proper nozzle selection.

- Check to make sure the pump pressure is properly set.

- Check the nozzle spray to be sure it is satisfactory. If the nozzle is clogged, it may be impossible to ignite the resulting spray.

- Check the spray pattern. Following the manufacturer’spressure chart, some burners give delayed ignition with the hollow cone sprays, in which case a solid cone nozzle may be the answer.

- Sometimes the next size smaller nozzle will help. Also, the smaller droplets will burn cleaner, decreasing the amount of soot and dirt.

- Installing a delayed opening solenoid valve on the nozzle line can usually help pulsation during start-up or shutdown.

Off-Center Flames

- These may be caused by off center location of the nozzle in the burner tube. The nozzle tube or bracket may be bent or improperly located.

- If the heavy flame always appears on the same side in a particular burner, this is due to a peculiarity of the air pattern in that burner and can’t be corrected by changing nozzles.

- A nozzle contaminated by sludge or other foreign matter will usually produce an off center flame.

Long Flames

A narrow spray angle always produces a long flame. High viscosity fuel can also be a cause since the spray angle tends to collapse. As mentioned before, this can sometimes be solved by increasing pump pressure and going to the next size smaller nozzle. Solid cone nozzles also produce a longer flame.

Frequently Asked Questions

What should I do on a job where it is difficult to clean up the flame?

- Check the flame to see whether it is off center (see discussion of off center flames above).

- Check the fan blades and if they are covered with lint and dirt, clean them.

- If this is a conventional liquid fuel burner, check for a burned-off retention head.

- Check the liquid fuel pressure to be sure that it is at least 100 psi.

- Check for a plugged line filter or pump strainer.

- If the smoke is at the outside edges of the flame, try a narrow angle nozzle.

- If the smoke occurs at the end of the flame, try a wider spray angle.

- The burner may have insufficient air capacity for this firing rate.

- The burner may have too high air capacity for this firing rate. This would mean that the burner head couldn’t handle a low firing rate.

- It might just be a very inefficient burner, which cannot be made to burn clean.

- The nozzle may be partially plugged, resulting in poor atomization.

- The liquid fuel may have a high viscosity or it might be cold, resulting in a collapsing spray.

- Get sufficient air into the boiler room. If necessary, put in an air intake pipe with a screen and storm cover.

The flame in a burner is always off center and heavy on the right side. I can’t find a nozzle that will straighten the flame.

- If the flame is always heavy on one side, the nozzle does not cause it. It would be impossible to make a nozzle spray that is heavy on one side and always have it come up on the same side of the burner.

- Check the position of the nozzle in the burner head. The chances are it is off to one side or the other.

- With a short burner tube, the air stream may be stronger on one side than the other. That will give the appearance of an off center flame.

- If the burner is installed to one side of the combustion chamber, the flame may also give the appearance of being heavy on one side.

- If the nozzle spray pattern is off center due to contamination or any other reason, it may make a flame which is heavy on one side, but it could be in any direction.

How do you cure pulsation?

- A hollow cone nozzle generally gives greater freedom from pulsation than a solid cone nozzle.

- A wider spray angle sometimes helps a pulsating condition. It may even be necessary to use a 90° nozzle. In this case, watch for smoke at the outer edges of the flame.

- Reduce the firing rate to the next smaller nozzle if it will carry the heating load.

- The combustion chamber may be too large, allowing the flame to leave the burner.

- Higher fuel pressure sometimes helps because it gives a more stable spray pattern and smaller droplets, which burn closer to the burner.

- Be sure there is air intake into the boiler room.

- Sometimes a flame retention burner will cure or improve a pulsating or rumbling condition.

I have a customer who complains of having soot particles on the floor around the boiler and other places in the basement. The flame is clean. What is the reason for this?

- Make sure that you have adequate chimney draft so that there is not a back-pressure in the smoke pipe when the burner starts. This type of complaint occurs with a long smoke pipe between the boiler and the chimney. If the smoke pipe does not have enough pitch, there may be a backpressure at the boiler connection even with sufficient chimney draft.

- Check for an obstruction at the point where the smoke pipe enters the chimney.

- Cement up all leaks in the boiler setting where soot might come out on the start.

- Install a delayed opening solenoid valve or ProTek® valve in the nozzle line to make smoother starts.

Care & Service Tips for Burner Nozzles

A liquid fuel burner nozzle is an intricate piece of hardware, designed to do an accurate job of atomizing and metering liquid fuel in the spray pattern best suited to a given burner. To help assure top performance of this vital component, we’ve put together a list of important guidelines for you to follow.

Annual Appliance Maintenance Checklist

Now that we are in the heating season, many burner service contractors are performing the annual clean-up or servicing of their customers’ appliances. What exactly does the serviceman do on these annual clean-ups? Let’s review a list of things that are usually involved from the experts at Beckett.

Request a 1-on-1 Consultation with a Delavan Technical Advisor

Have questions about our Care & Service Tips for Burner Nozzles guide? Have a particular issue with a nozzle that you just can’t seem to troubleshoot? Have general questions about how to optimize your annual appliance tune-up service to maximize your profitability? We’d love to help! Fill out the form below and we’ll be in touch within 48 hours to schedule your consultation.

Latest News

Keep up to date with the latest news from partners, events, our company and the wider industry.

Request a Consultation

Have questions about our spray-nozzles or fluid handling systems? Looking for help on a unique application? Need help with a budget estimate to determine overall equipment costs? Please don’t hesitate to reach out — we’d love to help.