Internal Mix

Construction and Materials

-

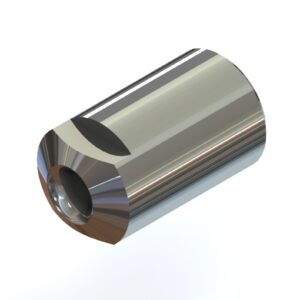

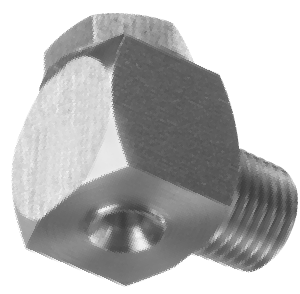

- Three piece construction: Nozzle Body, Distributor and Cap.

- Right angle version has atomising air enter from the side of nozzle and liquid from the back

- In-line version allows for the nozzle to be placed on a lance for simple plumbing. The length of the lance can vary by providing two concentric pipes and couplings.

A Swirl-Air™ adaptor could also be used.

- 316L Stainless Steel is standard

- Other materials available to special order.

Order Example

- P/N 50544-4 GPM Right Angle Internal Mix Nozzle.

- Maximum Recommended Pressure: 200 PSIg (14 Bar.G.)

- Maximum Recommended Temperature: 1000°F (540°C)

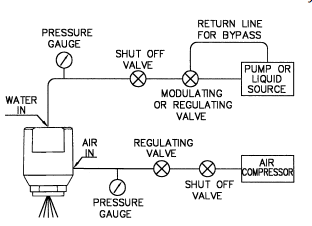

TYPICAL Installation

- Install nozzle as shown in schematic drawing. Make certain both pressure gauges are located as close to the nozzle as practical. Allow for pressure losses between gauges and nozzle when establishing settings. Shut off valves included for convenience, allowing nozzle removal without shutting down system.

Latest News

Keep up to date with the latest news from partners, events, our company and the wider industry.

Request a Consultation

Have questions about our spray-nozzles or fluid handling systems? Looking for help on a unique application? Need help with a budget estimate to determine overall equipment costs? Please don’t hesitate to reach out — we’d love to help.