Bypass™

Delavan's Bypass™ nozzle has won an Honours Award in the Vaaler Awards competition held by Chemical Processing magazine. The product was judged as a major contribution toward more efficient and effective operation of plants in chemical processing industries.

APPLICATION

- Evaporative cooling, chemical processing.

Features

- Flow rate is changed by means of a bypass valve without varying the supply pressure of using atomizing air or gas. (See flow diagram).

- Reduces the number of nozzles needed when gas inlet temperatures vary.

- In a bypass system, a portion of the input liquid may be diverted through a return line by means of a bypass valve. As the valve is opened, the total input flow increases. Delavan's Bypass™ nozzle's patented design minimizes this flow growth to avoid excessive pumping requirements and hydraulic power consumption. The input flow increase (when bypass valve is opened) can be as low as 15%.

- Nozzle can be located in high temperature zone and connected by concentric piping to adaptor in cool area.

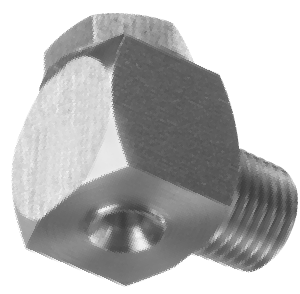

Construction and Materials

- Large passages, to minimize restriction and to avoid clogging.

- Nozzle cap and body easily removed from adaptor.

- Available in 316 L Stainless Steel only.

Order Example

- Refer to capacity chart for part numbers.

Maximum Design Pressure: 56 Bar.G.

Maximum Design Temperature: 540° (Bypass™ Nozzle), 150° (Adaptor).

Latest News

Keep up to date with the latest news from partners, events, our company and the wider industry.

Request a Consultation

Have questions about our spray-nozzles or fluid handling systems? Looking for help on a unique application? Need help with a budget estimate to determine overall equipment costs? Please don’t hesitate to reach out — we’d love to help.