*Pipe centres can be adjusted to suit customer’s existing installation.

The continuous casting of metals is a relatively new process in the steel industry, but tremendous strides in development have been made in recent years. In the constant pursuit of technological advancements, Delavan's engineering staff have worked with steel mills world-wide to implement many improvements in the casting process.

The result of much research and development is the Delavan Cool-Cast nozzle, which with its tightly uniform droplet size can significantly improve slab quality and reduce energy costs in your continuous casting operation. The table below provides an illustration of the typical droplet sizes.

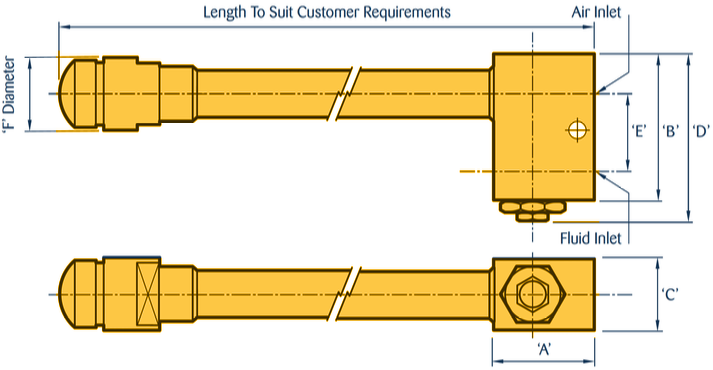

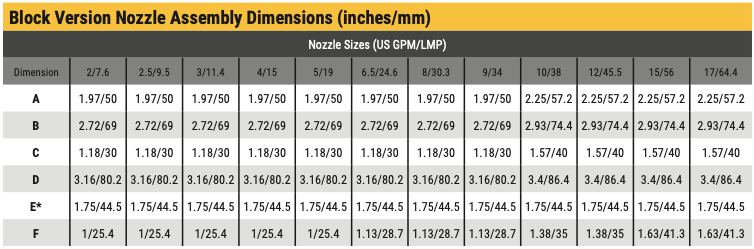

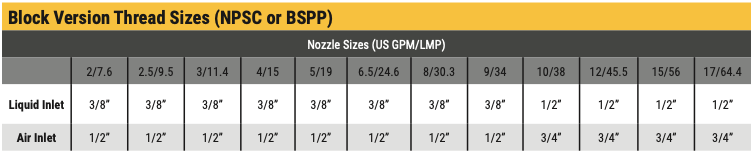

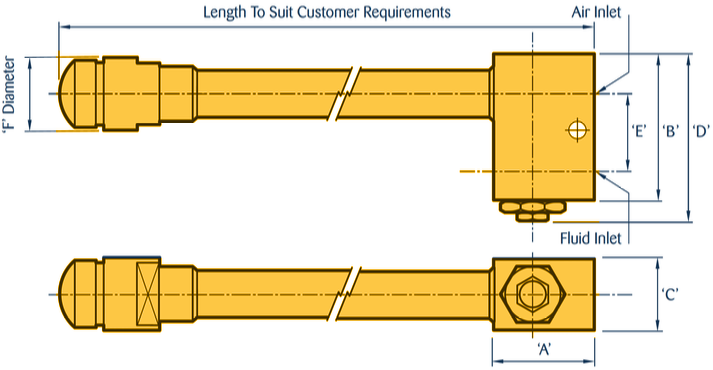

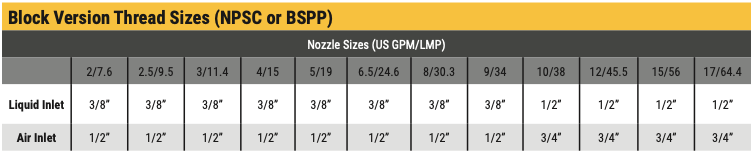

Producing steel in today's market from slabs to bar mills including secondary cooling during the casting process requires efficient spray nozzles. Delavan2s newest '91Block Style'92 Cool-Cast nozzle offers flexibility in alignment for tight space in-between the framed segments. The ability to use quick connect couplings with the parallel piping gives operators access to quick release nozzles during rebuilds. With interchangeable components, liquid and air can be easily adjusted to meet product changes for various grades of products. The all stainless steel construction extends the durability and life of the nozzle in harsh environments. Typically Cool-Cast nozzles produce results using less air than other types, further reducing cost of ownership. The '91Block Style'92 Cool-Cast nozzle has different thread sizes and liquid connections to avoid misalignment.

Our specialist design teams can also provide customised designs for your own Applications, contact our sales team on +44 (0)151 424 6821 or inside USA Toll Free: 1-800 Delavan for more information.

The Cool-Cast design consumes less air than conventional nozzles, which saves energy usage through reduced air compressor load.

Block Version (CCB)

USA Patent Application 11/736810

European Patent Application EP07251261.9

Patent Application in Japan 2007-108565

A full range of nozzles in different sizes are available for both assembly types and figures are available further in this brochure showing the relevant air consumption and liquid flow rates at a range of air and liquid pressures.

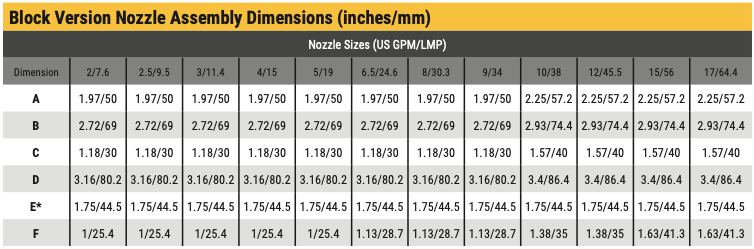

Below is a table showing the various options available to help when deciding which nozzle is right for your application. On the following pages are capacity charts showing the relevant air consumption and liquid flow rates at a range of air and liquid pressures corresponding to the flow rates shown below. Please be aware that the data in the charts shown on pages 7-9 was generated on Delavan test equipment. Actual figures may differ due to the effects of the local Installation.

Other Delavan nozzles used in Continuous Casting:

Flat Spray '96 AC, LF, LD, AD, LE

Solid Cone Spray '96 BI, BN, BQ, BT, BC

The Delavan RLD Flat Spray Nozzle has been designed for use in Hydraulic Continuous Casting Machines. The internal design of the nozzle provides a thicker spray footprint, thus resulting in an increased cooling efficiency over a standard flat spray nozzle.

The nozzle also includes a built in location fitting to eliminate incorrect alignment. Flow rates are available from 4-18 LPM (1-4.8 USGPM) at 2.8 BAR (40 PSI) with a spray angle of 80'ba.

*Pipe centres can be adjusted to suit customer’s existing installation.

Keep up to date with the latest news from partners, events, our company and the wider industry.

Have questions about our spray-nozzles or fluid handling systems? Looking for help on a unique application? Need help with a budget estimate to determine overall equipment costs? Please don’t hesitate to reach out — we’d love to help.