Assembly Procedure:

1. Place Nozzle Body (A) thread side up on a flat surface

2. Place Orifice O-Ring (B) in the Nozzle Body (A)

3. Place Orifice Disc (C) on top of the Orifice O-Ring (B)

4. Place Swirl Chamber (D) on top of Orifice Disc (C) either way up

5. Insert End Plate (E) over Swirl Chamber (D) bevelled side up

6. Install Screw Pin (F) into Nozzle Body (A), wrench until snug (Torque of 47.5 Newton/ Metres or 35 Pound-feet)

7. Drop Body O-Ring (G) onto Nozzle Body (A)

8. Screw Nozzle Body Assembly onto Adaptor (H), wrench until snug (Torque 68 Newton/Metres or 50 Pound-feet)

9. Finally ensure the complete assembly does not rattle

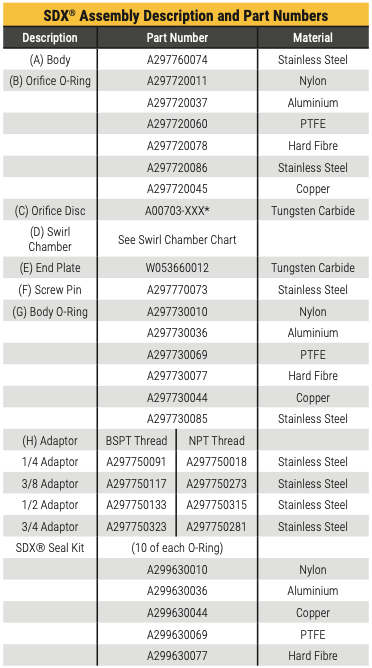

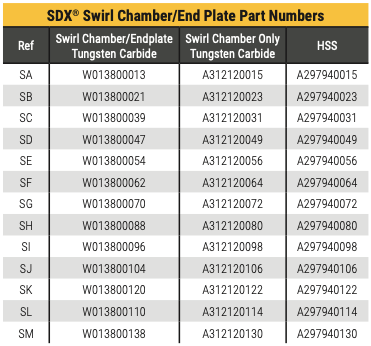

* Specify orifice size and swirl chamber suffix from capacity chart, on pages 24-25

Please Note: This chart is only a limited illustration of available sizes. Special materials are available on request for particular applications, please contact us for prices and delivery.