Assembly Procedure:

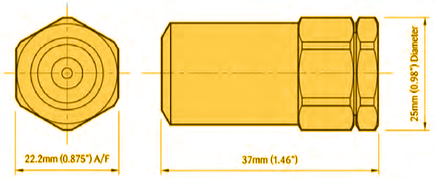

1. Place Nozzle Body (A) thread side up on a flat surface

2. Place the Orifice O-Ring (B) cone face down into the Nozzle Body (A)

3. Place the Orifice Disc (C) onto the Orifice O-Ring (B) protruding side down

4. Secure the Swirl Chamber O-Ring (E) onto the Swirl Chamber (D)

5. Place the Swirl Chamber Assembly (D+E) swirl side down onto the Orifice Disc (C) into Nozzle Body (A)

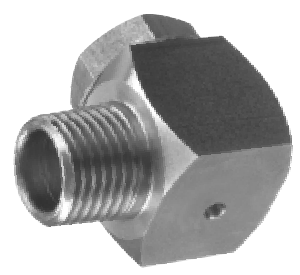

6. Secure the Adaptor O-Ring (F) into the recess on Adaptor (G)

7. Screw down the Adaptor (G) into the Nozzle Body (A) securing all components in place and hand tighten only

8. Finally ensure the complete assembly does not rattle

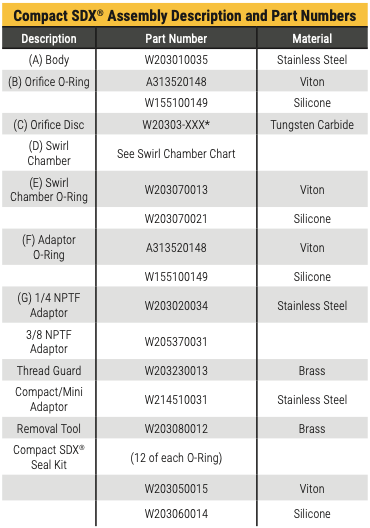

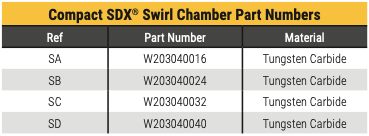

* Specify orifice size and swirl chamber suffix from capacity chart, on pages 24-25

Please Note: This chart is only a limited illustration of available sizes. Special materials are available on request for particular applications, please contact us for prices and delivery.