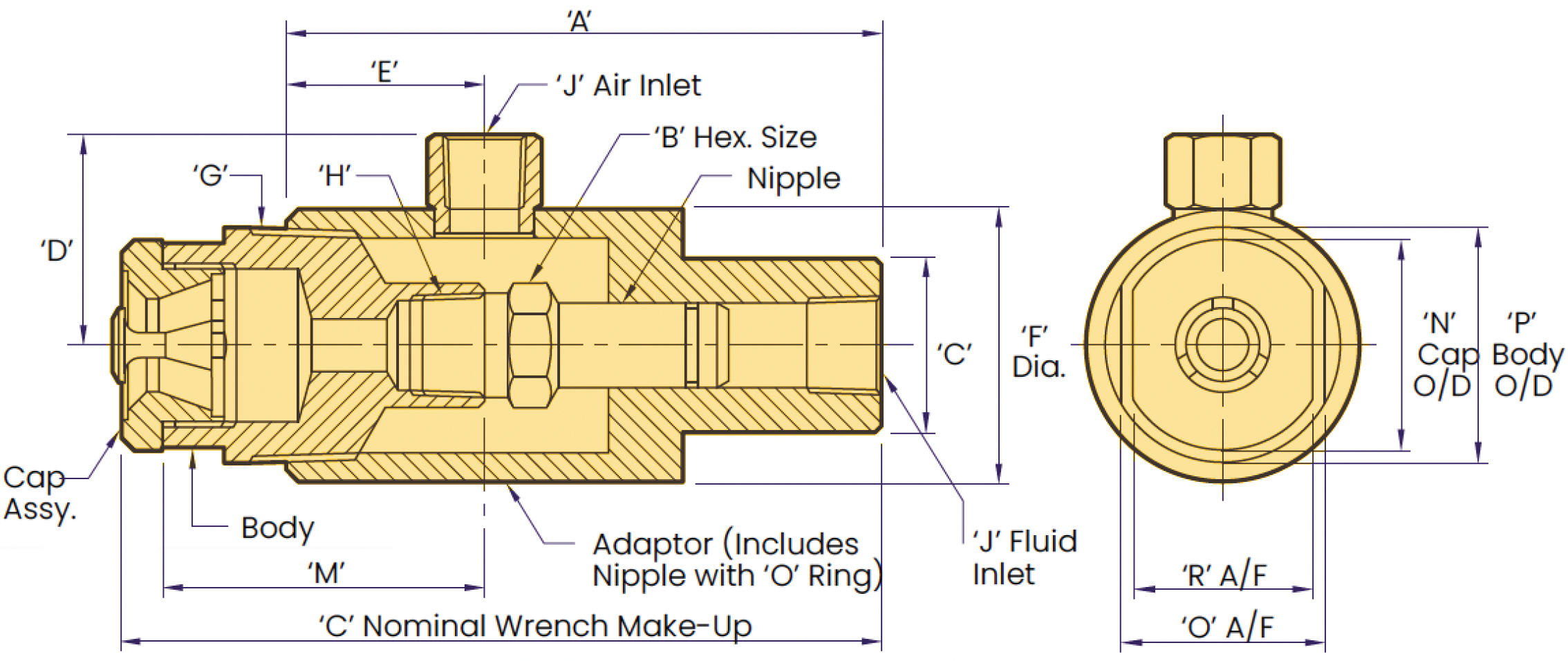

Liquid enters the nozzle axially, coming in contact with a tangentially introduced stream of air/gas or steam in the nozzle mixing chamber. The liquid impinges on the pintle plate and the interaction of gas and liquid creates extreme turbulence in the chamber. The swirling liquid, seeking an exit, impinges against the walls and distributor plate and then flows through the venturi-shaped orifice, where the droplets are exposed to extreme shear forces before impinging against a circular deflector ring and leaving the nozzle as a finely atomized spray cone. The deflector ring is held in position by a cone projecting from the distributor plate. This method eliminates struts that could interfere with the spray pattern. The progressive application of shear and inertial forces within the nozzle provide for a relatively high nozzle efficiency.

Keep up to date with the latest news from partners, events, our company and the wider industry.

Have questions about our spray-nozzles or fluid handling systems? Looking for help on a unique application? Need help with a budget estimate to determine overall equipment costs? Please don’t hesitate to reach out — we’d love to help.